Bryce C

DFW

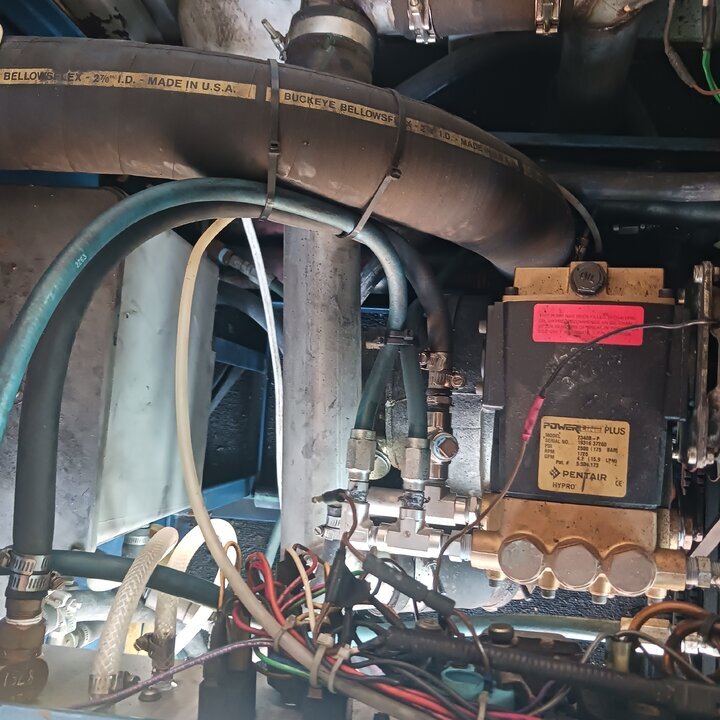

I'm going to go for it. I wonder if 3 days off will do the trick. 1st day blast the crud out of the waste tank with a high pressure spray gun and let it dry completely, next day pour the epoxy after somehow plugging the drain valve to prevent epoxy from getting into it, let it cure for a full day and get back to work on day 4. I think I have a small leak already.